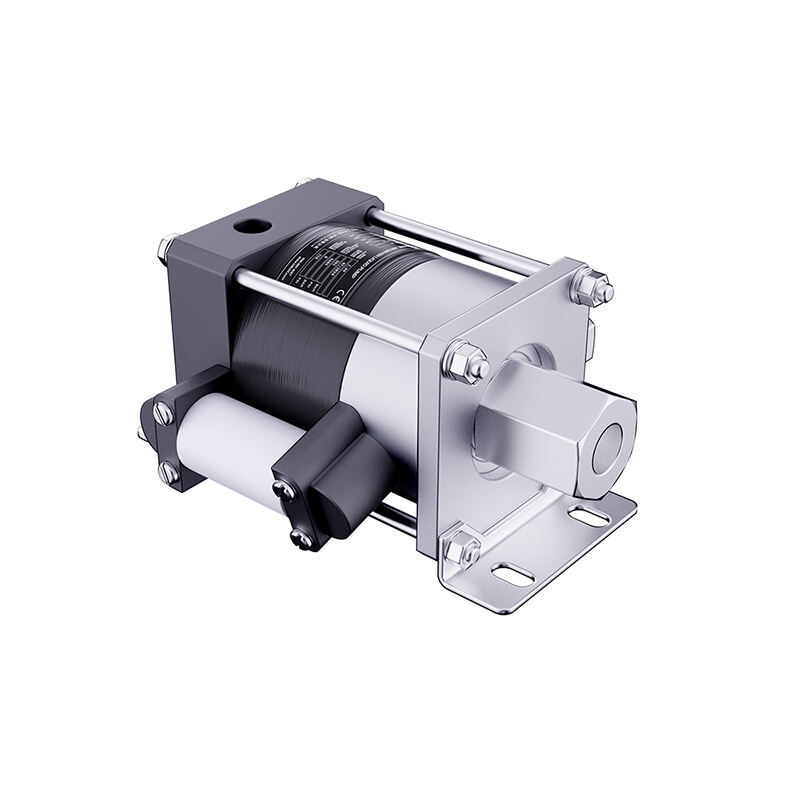

air driven liquid pumps

Air driven liquid pumps are innovative devices that harness the power of compressed air to move liquids efficiently and reliably. These pumps function without the need for electricity, making them ideal for use in hazardous environments. Their main functions include transferring, dosing, and circulating liquids in a variety of industrial processes. Technological features of air driven liquid pumps include corrosion-resistant materials, which extend the pump's lifespan, and their ability to handle viscous and aggressive fluids. These pumps find applications across industries such as chemical processing, pharmaceuticals, and food and beverage manufacturing, where safety and precision are paramount.